|

Luoyang Jinhui Machinery & Electronic Co.,Ltd

|

5.5 million UHMWPE powder

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

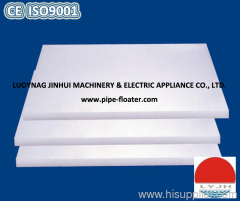

UHMWPE is a thermoplastic engineering plastic with a viscosity-average molecular weigh greater than 1.5×106

Brief introduction of UHMWPE:

UHMWPE is a thermoplastic engineering plastic with a viscosity-average molecular weigh greater than 1.5×106, and is made by polymerization of ethylene under the action of a catalyst. Its molecular weight has reached over 5 million, its five properties of abrasion, impact and corrosion resistance, self-lubrication, and absorption of impact energy are the best among the available plastics. It is called globally "marvelous plastics" UHMWPE, a new star of materials, will present a vigorous life and play an important part in many regions of the national economy.

Characteristics of UHMWPE:

1. Outstanding impact strength even at very low temperature.

2. Excellent sliding abrasion resistance, wear strength several times as large as steel.

3. Very low coefficient of friction.

4. Nonstick, self-lubrication properties.

5. Good chemical resistance.

6. Excellent anti-aging.

7. Hygienic and nontoxic.

8. Lightweight.

9. Hydrophobic, energy absorption and sound-dampening properties.

10. Excellent dielectric and insulating properties.

2. Excellent sliding abrasion resistance, wear strength several times as large as steel.

3. Very low coefficient of friction.

4. Nonstick, self-lubrication properties.

5. Good chemical resistance.

6. Excellent anti-aging.

7. Hygienic and nontoxic.

8. Lightweight.

9. Hydrophobic, energy absorption and sound-dampening properties.

10. Excellent dielectric and insulating properties.

Typical applications of UHMWPE:

Applications of UHMWPE are very extensive and it mainly applies to following aspects:

1.Building machinery, agriculture machinery, mining machinery; e.g. liners for silos, hoppers, dump trucks, railcars and chutes.

2.Transporting machinery: sliding guide, guide roll, bushing.

3.Packing, container and tubing: open-type pot, bucket, gasoline tank, gas tube, conveying tube of grain.

4.Pulp and paper industry: doctor blade, suction box cover, filter, chain conveyor plate and dewatering plate.

5.Textile machinery: loom picker, shuttle, stick, strap, cap, buffer, gear, pinion and small roller.

6.Chemical industry: pump impeller, pump housing, valve seats and valve gasket.

7.Medical, macromolecular material: artificial articulation, surgical parts.

8.Sport goods: ski and snowboard bottom surface, snowmobile drive sprocket, golf ball core.

9.Aviation and military: bulletproof vest, aircraft seat.

10.Others: lead-acid battery separator, screen plate of nuclear power plant, fishing rope.

1.Building machinery, agriculture machinery, mining machinery; e.g. liners for silos, hoppers, dump trucks, railcars and chutes.

2.Transporting machinery: sliding guide, guide roll, bushing.

3.Packing, container and tubing: open-type pot, bucket, gasoline tank, gas tube, conveying tube of grain.

4.Pulp and paper industry: doctor blade, suction box cover, filter, chain conveyor plate and dewatering plate.

5.Textile machinery: loom picker, shuttle, stick, strap, cap, buffer, gear, pinion and small roller.

6.Chemical industry: pump impeller, pump housing, valve seats and valve gasket.

7.Medical, macromolecular material: artificial articulation, surgical parts.

8.Sport goods: ski and snowboard bottom surface, snowmobile drive sprocket, golf ball core.

9.Aviation and military: bulletproof vest, aircraft seat.

10.Others: lead-acid battery separator, screen plate of nuclear power plant, fishing rope.

Product specification:

Item | Unit | SLL-2 | SLL-3 | SLL-4 | SLL-5 | SLL-6 |

Molecular weight | 104g/mol | 190~230 | 280~350 | 400~460 | 500-600 | 600-700 |

Density | g/cm3 | 0.93~0.94 | 0.93~0.94 | 0.93~0.94 | 0.93~0.94 | 0.93~0.94 |

Water Absorption (≤) | % | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

Granularity (20~40 Mesh) (≥) | % | 90% | 90% | 90% | 90% | 90% |

Temperature of deformation (≥) | ℃ | 80 | 80 | 80 | 80 | 80 |

Izod Impact Strength | KJ/m2 | No Break | No Break | No Break | No Break | No Break |

Bulk Density | g/cm3 | 0.42 | 0.42 | 0.36~0.42 | 0.42 | 0.42 |

Charpy Notched Impact Strength (≥) | KJ/m2 | 90 | 90 | 90 | 90 | 90 |

Tensile Strength at Break (≥) | Mpa | 32~35 | 32~35 | 35~40 | 35~40 | 35~40 |

Elongation at Break (≥) | % | 380 | 350 | 330 | 320 | 310 |

Wear by the Sand Slurry (≤) | % | 0.60 | 0.50 | 0.50 | 0.40 | 0.35 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!